With the increasing demand for advanced therapeutic drugs (ATPM) or CGT (Cell and Gene therapy), there are high hopes that cell and gene therapy could revolutionize the treatment of serious diseases. Whether autologous or allogeneic, genetically modified (such as CAR-T cells) or non-genetically modified (such as mesenchymal stem cells), or viral vectors, all relevant process steps, from cell selection, cell activation, gene modification, cell expansion, cell harvesting and formulation to bagging, need to be carried out in a reliable and safe, compliant environment.

▲Traditional training program

In the field of life sciences, cell culture is a critical and technically difficult job. However, there are many problems in the current artificial culture method, such as inconsistent quality, poor stability, high chance of contamination, low work efficiency, etc. These problems make cell culture face many challenges.

These challenges not only affect the efficiency and quality of cell culture, but also add a series of limitations. For example, due to the unreliability of manual operation, the consistency of cell culture is difficult to guarantee, which makes it difficult to repeat and verify the experimental results. In addition, the process of biological experiments is usually very long. Except for the real manual operation time, most of the time is spent waiting for the experimental process, which makes the experimental process time-consuming and laborious.

▲Bogong Science and Technology Training Program

In order to solve these problems, incubator robots and centrifuge robots have become new options to replace artificially cultured cells. By using incubator robots and centrifuge robots, not only the efficiency and quality of cell culture can be improved, but also the dependence on manual operation can be reduced, and experimental errors and contamination risks can be reduced.

In addition, the combination of these two devices can also realize the autonomous culture of cells, reduce the cost and risk of cell culture, and provide a new possibility for the development of biomedical research, drug development, and cell therapy.

▲The delivery of Bogong Science and Technology Training Program

Therefore, utilizing isolator technology to minimize human intervention in processing areas can greatly reduce the risk of microbial contamination of aseptically manufactured products in the environment.

Bogong Technology has an automated solution for cell cultivation, which not only provides a low-cost, high-efficiency clean inspection environment in a limited laboratory environment, but also ensures the sterility inspection and aseptic operation of the rapid sterilization function of the product. Automate or intelligentize a certain operation or step in the laboratory, such as automatic petri dish access, automatic centrifugal washing, etc., and perform all laboratory operations by issuing instructions to intelligent robots. At present, Bogong Technology has reached cooperation with cell industry applications, biomedical factories, medical testing institutions, and university research institutes to realize the project implementation.

01 Intelligent life science robot

The incubator robot is an intelligent biological experimental equipment that integrates multiple functions such as biological sample cultivation, automatic control, data acquisition and analysis. It can not only establish a unique uniform environment control technology through mathematical models such as gas simulation, ensure the uniform control of temperature, humidity, and carbon dioxide concentration in the box, and break through the key technical difficulties in maintaining environmental uniformity. It can also perform automated operations, such as switching the incubator, adding culture medium, replacing strains, etc., which greatly improves the efficiency and accuracy of the laboratory.

▲Incubator robot

Centrifugal robot is a kind of equipment for cell separation and washing, which can separate cells from culture medium through high-speed rotation, and remove impurities and harmful substances in culture medium. Compared with manual centrifugation, automated centrifuges have higher precision and efficiency, which can greatly improve the quality and consistency of cell separation and washing. By combining automation and intelligent technology, the operation of the centrifuge is completely handed over to the robot. Through preset programs or remote control, the centrifuge robot can automatically complete the centrifugation operation, greatly liberating the hands of the experimenter。

▲Centrifugal robot

l Intelligent monitoring: real-time data collection and analysis

The life science robot is equipped with an intelligent perception and monitoring system, which can collect data during the cultivation process in real time. It can measure key parameters such as temperature, humidity, gas concentration, etc., and perform data interpretation and trend prediction through built-in analysis algorithms. This allows researchers to obtain experimental results in a timely manner, monitor the progress of the culture, and make adjustments as needed.

l Automatic control: accurately simulate the cultivation environment

Traditional incubators need to manually adjust parameters such as temperature, humidity, and gas concentration, while incubator robots use advanced automation technology to automatically control and maintain the stability of the culture environment according to preset experimental requirements. Whether simulating a specific temperature gradient, precisely controlling humidity, or adjusting gas composition, the robot is able to operate autonomously, reducing the burden on experimenters while ensuring the accuracy and stability of the experimental environment.

l Remote operation: monitor and control anytime, anywhere

Through network connection, researchers can remotely access the robot through computers or mobile devices at any time and any place, and monitor and control the cultivation process in real time. This allows them to understand the experimental status at any time, obtain real-time data, and make adjustments to the experimental environment, thereby improving the efficiency and controllability of the experiment.

l Intelligent control: intelligent analysis and fault warning

The centrifuge robot is equipped with an advanced data-based control management system, which can perform intelligent analysis and processing according to the characteristics of different samples. It can automatically adjust the centrifugation parameters according to the experimental requirements, and has fault warning and automatic alarm functions to ensure the safety and stability of the experimental process. At the same time, the robot also has data recording and traceability functions, allowing researchers to easily check experimental data and improve experimental reproducibility.

02 Application scenarios

l Microbial culture: It can be used for microbial culture, such as bacteria, viruses, cells, etc., to provide support for disease prevention, drug development and other fields.

l Preservation of biological samples: It can preserve precious biological samples, such as sperm, eggs, stem cells, etc., and provide important support for reproductive medicine, gene editing and other fields.

l Separation of biological samples: It can be used for the separation of various biological samples, such as protein, DNA, RNA, etc., to provide support for biological research, drug development and other fields.

l Cell culture: It can be used for cell culture and provide support for biomedicine, reproductive medicine and other fields.

l Microbial research: It can also be used in microbial research, such as bacteria and viruses, to provide support for disease prevention, environmental monitoring and other fields.

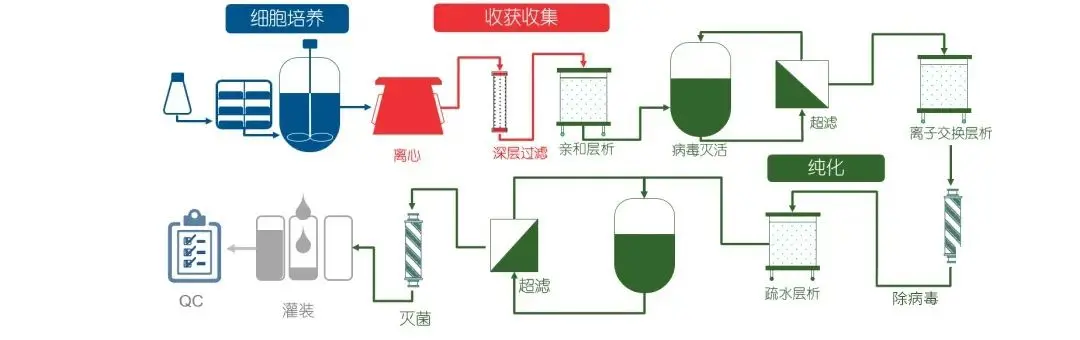

▲ Batch cell line construction is the core of biopharmaceuticals

▲ Monoclonal antibody production process

▲CAR-T cell therapy process

In general, through digital and intelligent empowerment, the cell cultivation automation solution breaks through the information islands of various platforms, realizes the traceability of closed-loop control and control of the whole process of data information, and can not only provide digital technical support for laboratory sample management, experimental research, etc. , can also automatically identify safety hazards with the help of smart probes and AI algorithms, and sensors can detect indoor environmental indicators in real time to ensure the safety of personnel and the environment in the laboratory.

In the future, Bogong Technology will continue to polish life science scenario solutions, continue to improve technology, deepen the industry, empower the future medical industry, and bring new application scenarios.