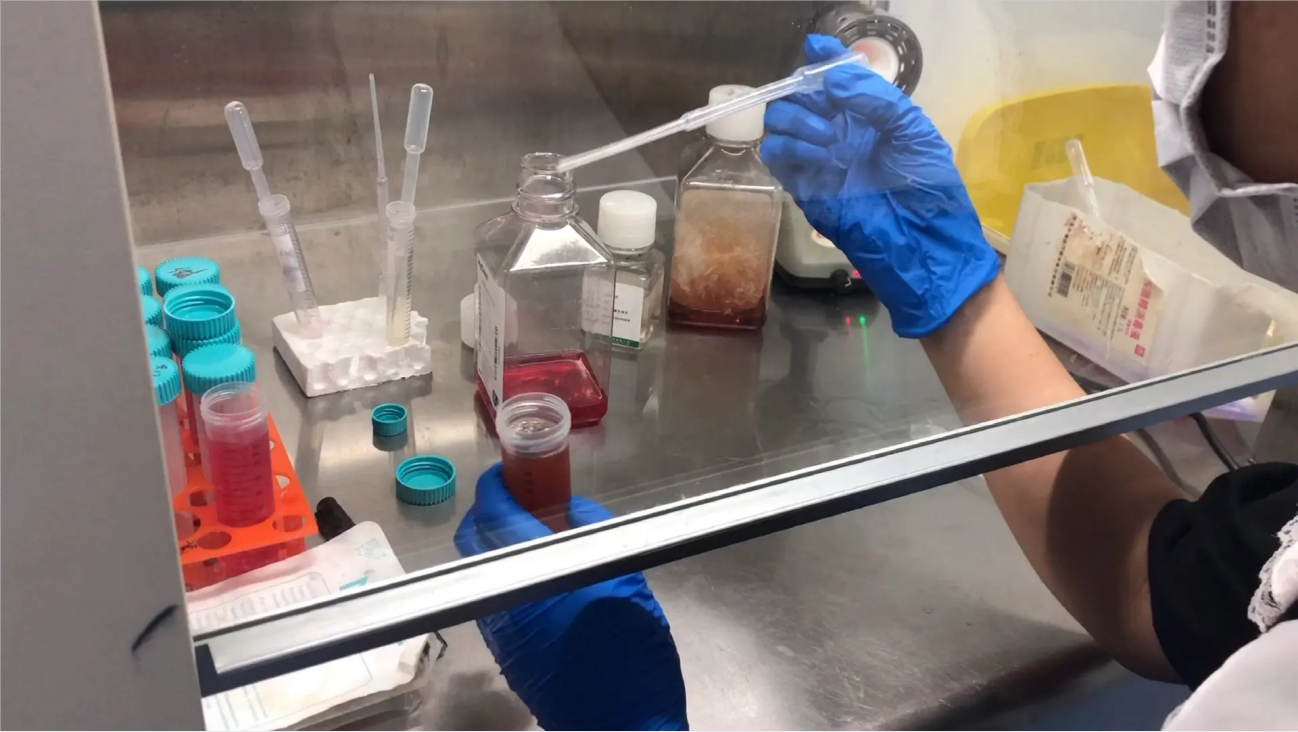

In the process of culturing cells, changing the medium is a routine operation, but improper operation can also affect the growth of cells. By changing the medium, the metabolic waste produced by the cells during the growth process is removed, and fresh serum-containing medium is added to make the cells grow and reproduce better.

In the research and development of drugs, vaccine research, and many academic discussions, cell culture experiments will be carried out to obtain new research content. Therefore, laboratories or research institutes will also produce corresponding cell culture waste liquid that needs to be treated, which is more harmful than general industrial waste water treatment.

The cell culture waste mainly comes from the disinfection waste discharged from the cell culture laboratory, the cleaning water of the culture dish or the lost liquid reagent, etc. Because the experimental bodies and reagents used in each research project are different, the composition of cell culture waste liquid is very complex, and the water contains a large number of microorganisms and refractory substances. Some cell culture laboratories may also contain toxic and harmful substances. The culture waste liquid is discharged irregularly, the concentration is high, and the water quality fluctuates greatly, so it is difficult to deal with it. Manual waste liquid treatment VS robot automatic waste liquid treatment

The cell culture waste mainly comes from the disinfection waste discharged from the cell culture laboratory, the cleaning water of the culture dish or the lost liquid reagent, etc. Because the experimental bodies and reagents used in each research project are different, the composition of cell culture waste liquid is very complex, and the water contains a large number of microorganisms and refractory substances. Some cell culture laboratories may also contain toxic and harmful substances. The culture waste liquid is discharged irregularly, the concentration is high, and the water quality fluctuates greatly, so it is difficult to deal with it. Manual waste liquid treatment VS robot automatic waste liquid treatment

Waste liquid treatment in traditional laboratories requires manual operations, increasing the risk of biological contamination

Solve the needs of laboratory automation waste liquid treatment and cell extraction

The cell waste treatment system is one of the infrastructures that must be used in biological laboratories.

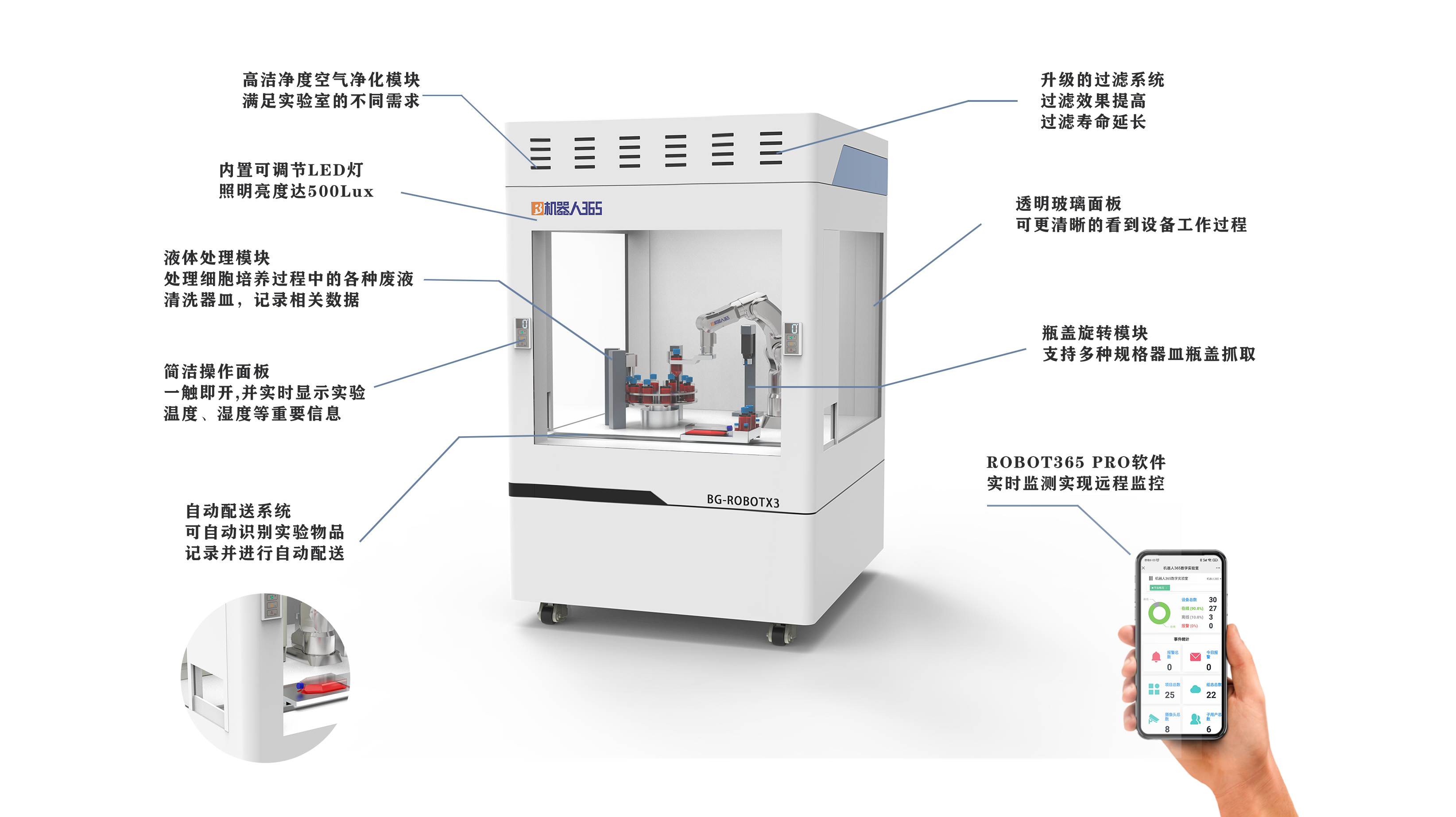

The waste liquid robot independently developed by Bogong Technology is mainly used to collect and dispose of the chemical waste liquid generated in the laboratory. When the waste liquid is full, the system can handle the waste liquid cleaning work in time by using the liquid level sensor and the control panel. The built-in filter collects harmful substances, and all materials have high strength and corrosion resistance, helping to create a safe and environmentally friendly smart laboratory.

Product Structure

It can be used for the suction of various laboratory liquids, including the residual liquid after the experiment, the supernatant of centrifuge tubes, etc., especially suitable for pumping the supernatant of the culture medium in the clean room. Adopting an innovative one-piece body structure, the waste liquid tank and vacuum pump are concentrated in the same workstation, which is convenient for overall movement and better fixes the waste liquid tank. Equipped with a full range of suction kits, it can be used for liquid suction of various containers including culture dishes, culture bottles, and 96-well plates.

Product parameters

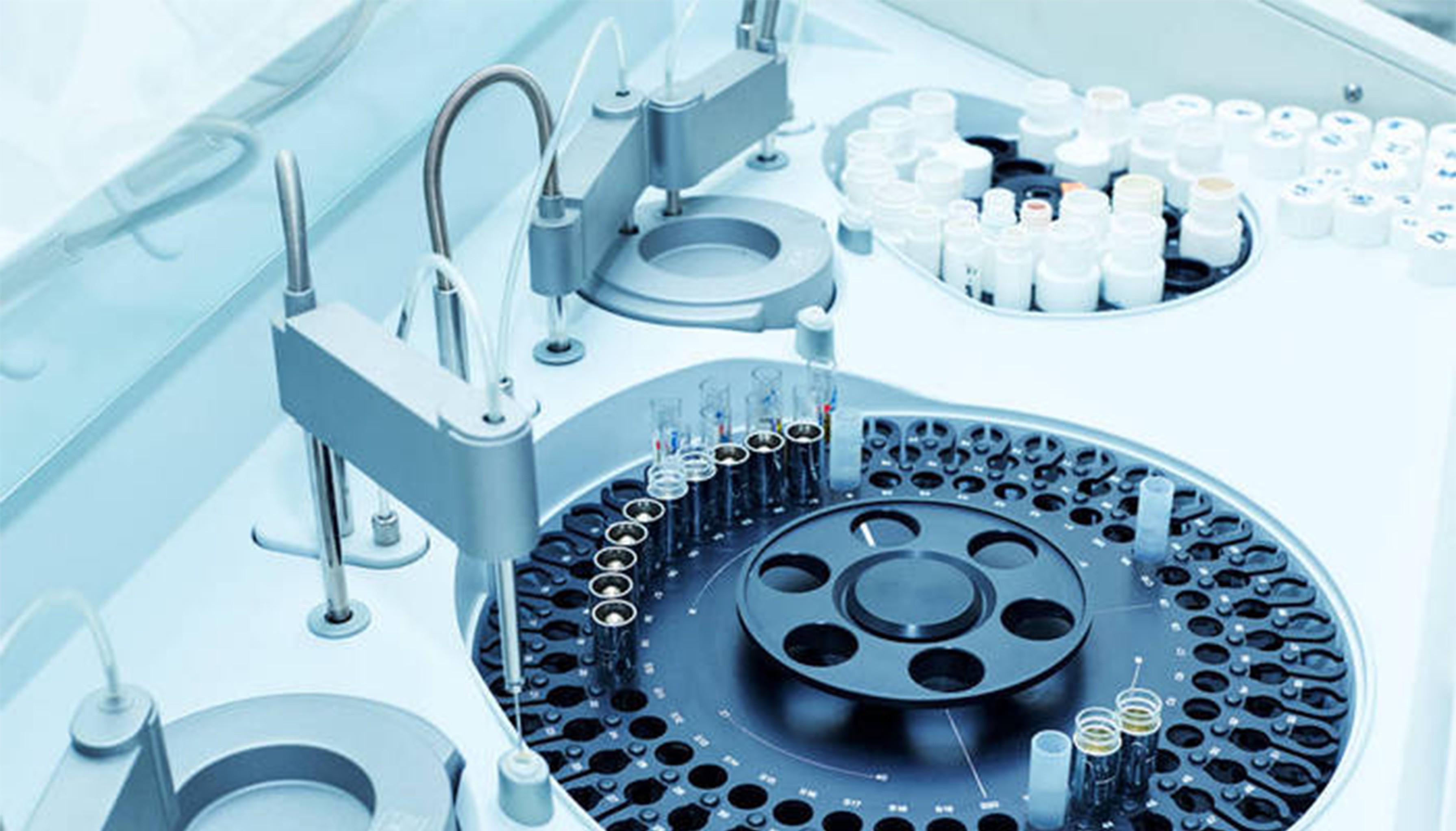

Safe stand-alone waste liquid treatment system

The waste liquid treatment system is mainly used for the collection of critical liquids or dangerous liquids, the treatment of pathogens, liquid treatment in any class III or class IV biohazard laboratory. The oil-free membrane pump achieves quiet operation and can withstand pressures from –250mm to 650mm Hg. When the target vacuum is reached, the membrane pump will automatically shut down. When vacuum pressure is applied, the membrane pump is automatically activated to maintain a constant vacuum pressure, which can be used for gentle suction of small plates and dishes and fast evacuation of large containers.

Significant advantages of stand-alone waste liquid treatment system

1. Good practicability, suitable for waste liquid treatment in various laboratories;

2. High degree of automation, simple operation, no special personnel on duty;

3. The liquid detection system prevents the bottle from being overfilled;

4. Control knob to realize infinite vacuum setting from –250mbar to –650mbar;

5. All liquid-immersed parts, such as bottles, caps, pipes and joints, can be sterilized by high temperature and high pressure;

6. Intelligent software controls the whole process, and automatically completes the whole process of opening the cap of the sample bottle, absorbing liquid, and separating.

Application Scenario

1. Cell Culture

Through cell culture, a large number of cells can be obtained, and it can also be used to study cell signal transduction, cell anabolism, cell growth and reproduction, etc.

2. Biopharmaceuticals

A class of products for prevention, treatment and diagnosis can be manufactured using the principles and methods of microbiology, chemistry, biochemistry, biotechnology, and pharmacy.

3. Medical testing

Microbiology, immunology, biochemistry, genetics, hematology, biophysics, cytology, etc. are tested on materials taken from the human body.

4. Research institutions

The whole process is intelligently controlled automatically, and the operator is highly replaceable. It is a safe, fast and efficient automation equipment.